Heat Shrink Insulating Tubing

Palapala noi

1. Hoʻohana no ka uila uila a hiki i 36kV

2.Protection kū'ē i ka makū a me ke kaomi

3. He kūpono no ka hoʻopau ʻana i ke kaula a me ka pale insulation hoʻohui waena

Hiʻona

1.Hot melting adhesive hāʻawi i ka wai ʻoi aku ka maikaʻi

2.Coating type: ka uhi kiʻiʻoniʻoni

3.Excellent corrosion kū'ē

4.UV kū'ē a me ka weathering kū'ē

5. Halogen-ʻole

6.Superior uila a me ka mechanical waiwai

7.Shrinkage lākiō 3:1

8. Medium pā

Hiʻona

1.Preferable uila lako hana

2.Reliable insulation

3.Superior hermetic sealing

4.Excellent wela / anuanu hōʻoia, wai, Anti-kahiko ,

5.Hoʻohana nui ʻia ma ke kahua o ka mana uila, uila, petroleum, ʻenekinia kemika, kūkulu a me ka kamaʻilio

ʻO ka hana ʻana o nā paipu wela wela e koho mua i ka masterbatch kūpono, a laila koho i nā mea kōkua e hana i nā kikoʻī kikoʻī.

ʻO ka pahu hale wela.

1. ʻO ke kaʻina hana o ka puʻupuʻu wela wela ka mea mua i ka hana ʻana i ka polyene leech masterbatch: hoʻohui ʻana i nā kumu kumu polyene leech me nā mea kōkua hana like ʻole.

Kaumaha ʻia nā mea e like me ka ratio formula a laila hui ʻia: hoʻokomo ʻia nā mea i hui ʻia i loko o kahi extruder twin-screw a pelletized e hana i ka polyene leech functional masterbatch.

2. Ke kaʻina hana hoʻoheheʻe huahana: e like me ke ʻano o ka huahana, hiki ke hoʻohana ʻia nā ʻano ʻelua o ka extrusion screw hoʻokahi a me ka hoʻoheheʻe injection.

No ka hana ʻana a me ka hana ʻana:

1. Single-screw extrusion 'ano: nui hoʻohana 'ia no ka extrusion hoʻoheheʻe 'ana o ka wela hoʻoheheʻe paipu, e like me hookahi-pā wela-shrinkable paipu, palua-pā wela-shrinkable paipu me ka glue, a me waena mānoanoa.

ʻO nā paipu wela o ka pā, nā paipu wela wela, nā paipu wela wela a me nā huahana ʻē aʻe i hana ʻia a hana ʻia e ka extrusion screw hoʻokahi.

Pono e loaʻa i ka laina hana hoʻoheheʻe wela ka mea e like me kēia: extruder (heat sink tube forming), production mold, cooling water tank, tension device, a

Mea hoʻopaʻa disk, etc.

2. Hoʻoheheʻe ʻia: hoʻohana nui ʻia no ka hana ʻana i nā ʻāpana ʻano kūikawā hiki ke wela, e like me nā pāpale wela wela, nā pale umbrella wela, nā moena manamana lima wela a me nā huahana ʻē aʻe.

Hoʻohana lākou a pau i ka hoʻoheheʻe ʻia ʻana, a pono nā mea hana e hoʻokomo i nā mīkini hoʻoheheʻe injection a me nā mold injection.

3. ʻO ka hana koʻikoʻi e hiki mai ana, ʻo ia ka hoʻopili ʻana i ka radiation.ʻO nā huahana i hana ʻia e ka extrusion a i ʻole ka hoʻoheheʻe ʻia ʻana he mau molekala laina laina.

ʻO ka hoʻolālā, ʻaʻole i loaʻa i ka huahana ka "hana hoʻomanaʻo", a ʻaʻole lawa ka hana ʻana o ke kūpaʻa wela, ke kū ʻana o ka wā kahiko, a me ke kūpaʻa.

Hoʻololi i ke ʻano molekala o ka huahana.ʻO ke ʻano hana a mākou e hoʻohana pinepine ai ʻo ia ka hoʻololi ʻana i ka hoʻololi ʻana i ka radiation crosslinking: electron accelerator radiation crosslinking, cobalt source radiation

Hoʻopili keʻa, hoʻopili kemika peroxide, i kēia manawa hoʻololi ka mole mai kahi ʻano mole mole laina a i kahi ʻōnaehana pūnaewele.Ke hala nei nā huahana extruded

Ma hope o ka hoʻopili ʻana, loaʻa iā ia kahi "hopena hoʻomanaʻo", kahi e hoʻonui nui ai i ka pale wela, nā waiwai mechanical, a me nā waiwai kemika o ka paipu wela.ʻO ka pākaukau kikoʻī

I kēia manawa ua hoʻololi ʻia ka paipu wela mai ke kūlana o ka hoʻomanawanui a hiki i ke kūpaʻa ʻole, ke kūʻokoʻa o ka wā kahiko, ka pale ʻana i ka abrasion, a me ke kūpaʻa ʻana i ke kino.

4. Hoʻonui ʻia: ʻO ka huahana i hoʻololi ʻia e ka radiation crosslinking ua loaʻa i kahi "hopena hoʻomanaʻo kino", a he kiʻekiʻe kona.

Hana hoʻoheheʻe ʻole ma lalo o ka mahana.Ma hope o ka hoʻomehana ʻana i ka wela kiʻekiʻe, ka puhi ʻana a me ka hoʻoluʻu ʻana, lilo ia i ka wela wela shrinkable tube, a laila e like me ka paipu.

Hiki ke ʻoki ʻia a paʻi ʻia ke kūlana maoli o ka paʻi huahana i hoʻopau ʻia a paʻi ʻia e like me nā pono o ka mea kūʻai aku.Loaʻa nō hoʻi ka ʻeke maʻamau kūʻokoʻa.

hana

| Hoao | ʻAno hoʻāʻo | Koi |

| Hana wela | UL 224 | -50 a i+125 ℃ |

| Ka ikaika tensile | ASTM D 2671 | ≥14 Mpa |

| ʻO ka hoʻolōʻihi i ka wā hoʻomaha | ASTM D 2671 | >400% |

| ʻO ka elongation i ka wā hoʻomaha ma hope o ka ʻelemakule wela | ASTM D 2671 158 ℃ / 168 hola | ≥300% |

| Hoʻemi lōʻihi | UL 224 | 0±5% |

| pā pāpaʻi hapa | ASTM D 2671 | <30% |

| Hoʻopaʻa ahi | VW-1 | Holo |

| Ke kū'ē leo | IEC 93 | >1014Ω.m |

| Paʻa keleawe | UL224 | Holo |

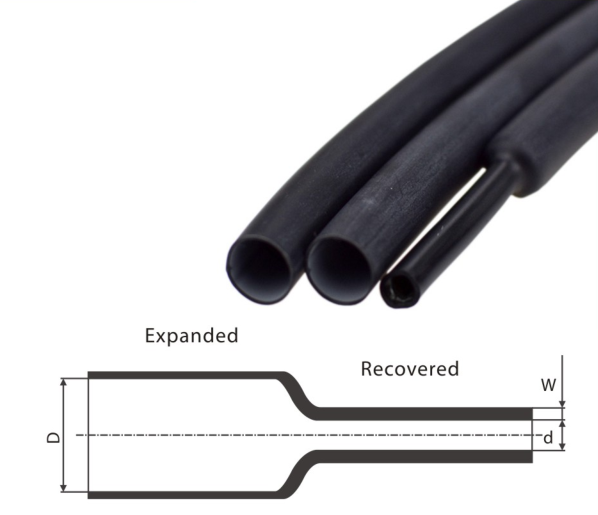

| ʻAno | Kaulana Anawaena (mm) | Hoʻonui (mm) | Loaʻa (mm) | |

| D(min) | d(max) | W(min) | ||

| RSG-15/5 | 4.5-8 | 15 | 5 | 1.5 |

| RSG-20/8 | 6.5-14 | 20 | 8 | 1.8 |

| RSG-28/10 | 12-18 | 28 | 10 | 1.8 |

| RSG-35/14 | 17-27 | 35 | 14 | 2 |

| WRSG10-28/10 | 6.5-14 | 28 | 10 | 2.2 |

| WRSG10-34/14 | 17-27 | 34 | 14 | 2.3 |

| WRSG10-40/18 | 17-30 | 40 | 18 | 2.5 |

| WRSG10-50/20 | 17-35 | 50 | 20 | 2.5 |

| WRSG35-50/20 | 17-35 | 50 | 20 | 3 |

| WRSG35-60/22 | 21-45 | 60 | 22 | 3 |

| WRSG35-70/25 | 24-52 | 70 | 25 | 3 |